- Products

- Why Nudura

- Nudura Project Applications

- Training Academy

- Resources

- Company

Common ICF Myths and Misconceptions

Insulated Concrete Forms (ICFs) offer a sustainable, safe and cost-effective building option for contractors, architects and owners. Many builders and designers have embraced this technology and their benefits, however some professionals in the construction field remain hesitant due to false preconceptions about their performance and installation process.

Here are the top myths about ICFs and the truth behind them.

Myth: ICFs are too expensive.

ICFs are cost-effective when considering all components of exterior wall assembly and the energy savings they provide. The forms combine multiple building steps into one, which reduces time and expenses during construction. Projects built using ICFs are also more energy efficient due to their air-tight continuous insulation which optimizes usage of heating and cooling systems and cuts operational costs for the owner.

Myth: Only underground rooms are safe.

ICFs can be used to build above ground and below ground structures, ensuring safety from natural disasters and extreme weather conditions in all climates. With a steel-reinforced concrete core held in place by dual-sided continuous insulation, Nudura Insulated Concrete Forms offer wind resistance of up to 250 mph (402 kph), a fire protection rating of up to 4 hours, impact resistance from wind-blown debris and superior resistance against seismic forces. They also have become the standard for safe rooms and storm shelters built according to FEMA guidelines that can withstand tornadoes.

Myth: ICFs can only be used for residential foundational walls.

While Insulated Concrete Forms are great for constructing highly insulated, watertight basements, their applications extend beyond foundational walls. ICFs are selected for many different types of projects, including pools, schools, military structures and multi-floor commercial and residential buildings. Any wall you would build with wood, cast-in-place concrete, CMU or tilt-up can be built with ICFs.

Myth: ICF construction is too complicated.

Like other construction methods, ICFs should be installed by certified professionals. With proper training, ICF offer a fast, seamless process for structural walls that adhere to building codes. Online and in-person courses are available to help builders of all experience levels learn the basics of ICF installation. According to Keven Rector at Nudura, ICFs “require less shipping space and manpower than other methods" to streamline construction.

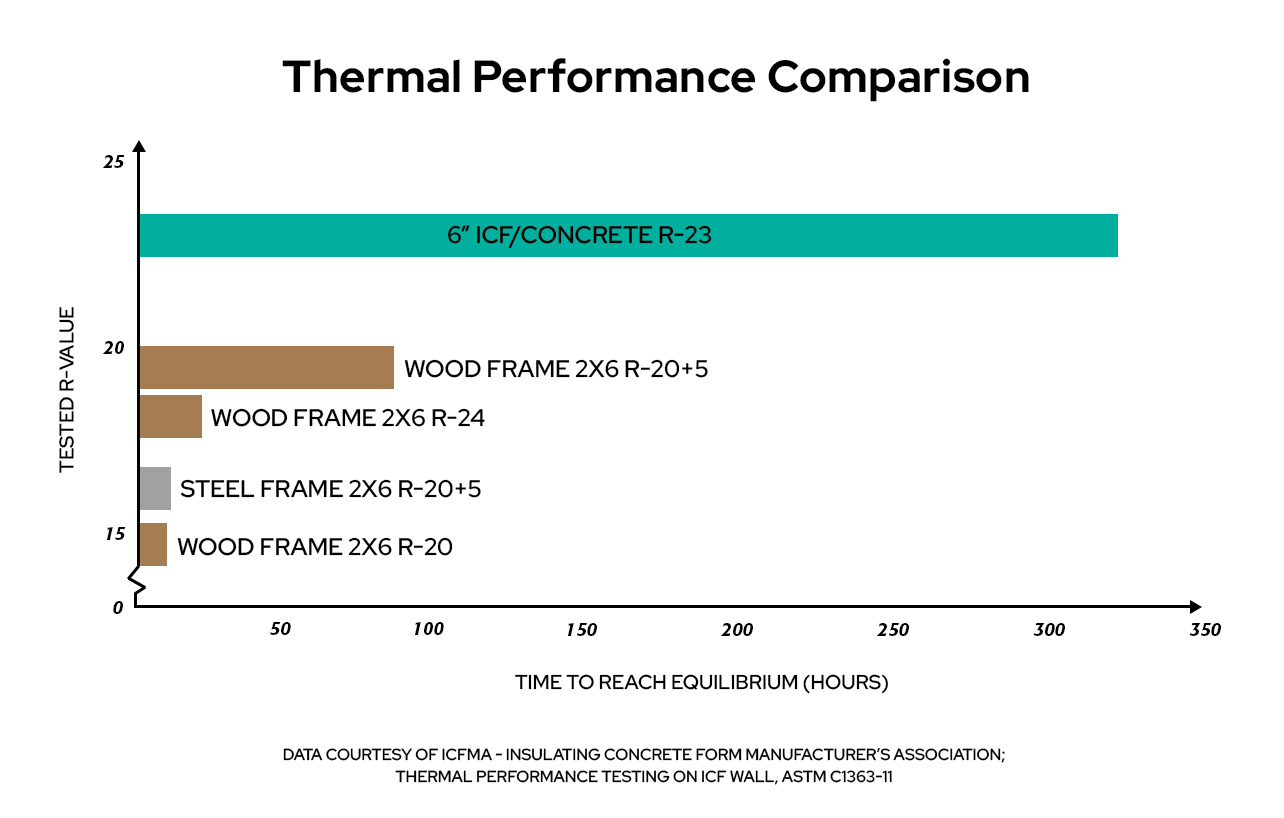

Myth: An R-20 cavity wall is just as good as an ICF R-23 Mass Wall with continuous insulation.

The thermal mass and continuous insulation of ICF walls have shown to greatly affect the performance of building enclosures. The Insulated Concrete Form Manufacturers Association (ICFMA) completed multiple comparative thermal performance tests assessing wood and steel stud walls versus an R-23 ICF wall, which confirmed that the ICF wall performed 60% better than a typical R-20 wood framed wall. During testing, heat was applied to both assemblies to determine their thermal performance. ICF walls took over 2 days before the interior temperature decreased, whereas the temperature of the wood structure dropped immediately after the heat source stopped. These results demonstrate that in the real world, ICF walls can maintain temperature for longer, while a wood-framed building would require heating or cooling immediately to stabilize the indoor environment.

Myth: ICFs are only effective in cold climates.

ICFs ensure thermal efficiency in both cold and warm environments with their continuous insulation and higher R-value, keeping the interior climate stable regardless of the outside temperatures. This innate consistency lowers usage of mechanical heating and cooling systems, which reduces an owner’s monthly utility bills. During construction, ICFs can also be installed in virtually any climate no matter the weather or time of year.

Myth: ICFs are difficult to use for design and limit versatility.

This myth has been proven false in numerous instances. In fact, ICFs increase design versatility and compatibility with various exterior finish options compared to conventional building methods. ICFs can be clad with brick, stone, CI panels, siding and architectural shapes with ease. The strength of ICF walls means they can accommodate wider openings in their designs such as bay windows, arched entryways and even 58-foot airplane hangar doors. Curved walls can be created by cutting the ICF blocks on-site or ordering radius forms pre-cut in the factory. Nudura ICFs are invaluable to new construction for eye-catching, limitless design possibilities.

Myth: You are unable to downsize your HVAC system when converting to construction with ICFs.

The superior insulation provided by ICF assemblies stabilizes interior temperatures on its own, even in extreme weather, minimizing the time that heating and cooling systems must run. If a contractor is reluctant to downsize an HVAC system after committing to ICF construction, this can happen for many reasons. Contractors may resist downsizing to protect themselves from customer complaints of the building being too hot or too cold throughout the year. While this fear is understandable, this often leads to oversizing HVAC systems, rather than “rightsizing” them.

Another common reason is that energy modeling programs may fail to recognize the real-world performance of ICF walls. The models rely on nominal R-value inputs and assume higher leakage rates. However, R-value is not the only metric that determines in-situ performance, and it is important to consider the drastic reduction in HVAC load that ICF walls provide.

CONTACT US

We’re committed to supporting homeowners and design professionals who are interested in or use our products. We’re always happy to help and provide more information.