- Products

- Why Nudura

- Nudura Project Applications

- Training Academy

- Resources

- Company

ICFs vs. CMU: 7 Frequently Asked Questions

Learn about the similarities and differences between Insulated Concrete Form and concrete block construction methods as it relates to strength, ease of installation, cost, energy-efficiency and design versatility with these ICF versus CMU FAQs.

What is the difference between Insulated Concrete Forms (ICFs) and Concrete Masonry Units (CMUs)?

Both ICFs and CMUs are used for building basement and above-grade structural walls in residential and commercial construction. ICF blocks have two layers of expanded polystyrene (EPS) connected by a web system that are filled with concrete and steel-reinforced to increase the durability and energy efficiency of the structure. Nudura ICFs are available in straight forms, corners, and curves for added design flexibility.

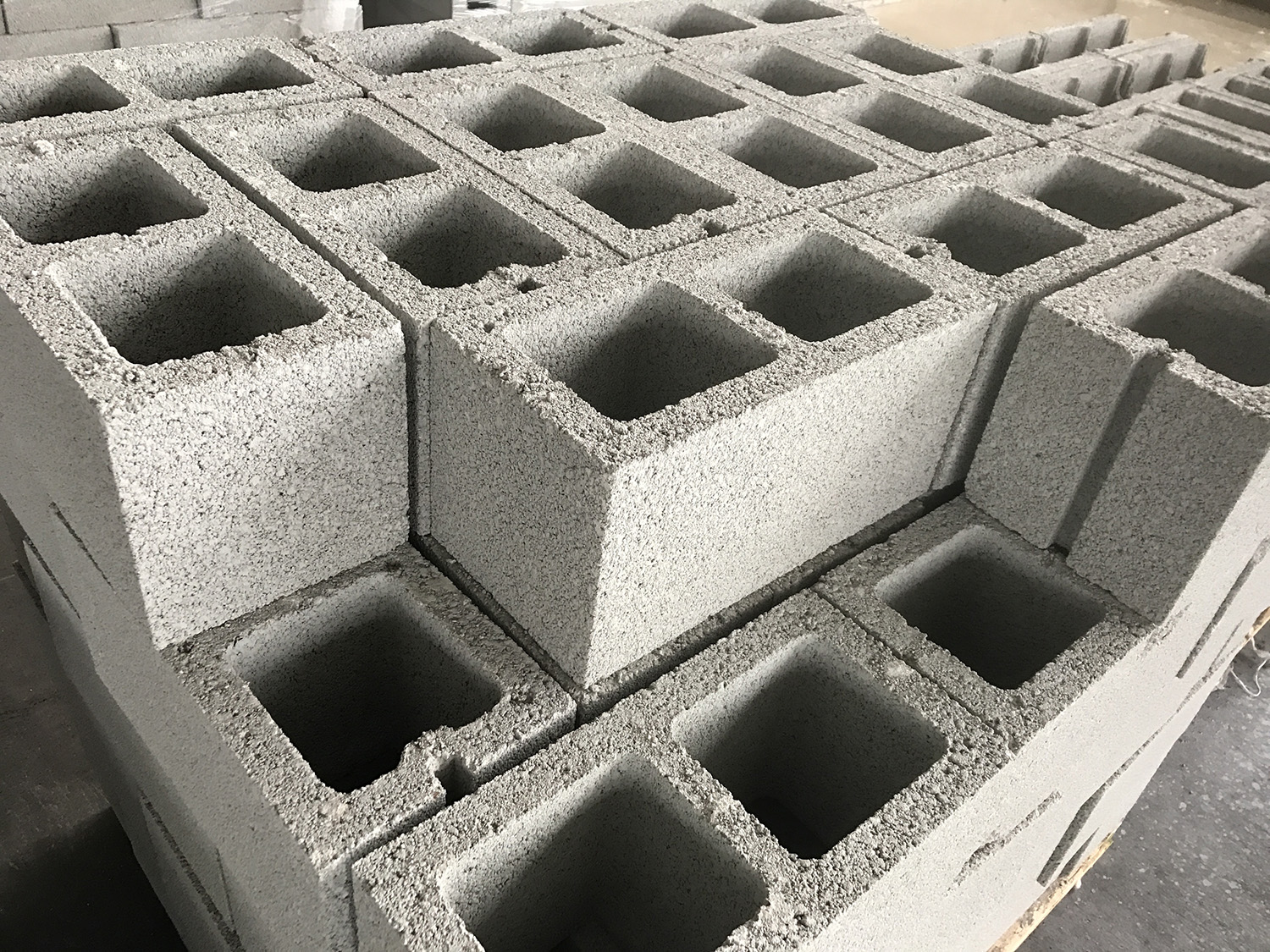

CMU walls are built by stacking cinder blocks, reinforcing with steel and securing with mortar. This system is not as strong as an ICF assembly and requires additional materials to waterproof the building envelope and achieve adequate thermal performance. The standard rectangular CMUs also limit the building’s design capabilities.

Which is stronger, ICFs or CMUs?

Insulated Concrete Form walls are more durable than CMU walls. The continuous insulation on the interior and exterior of the assembly helps the inner concrete cure more effectively for a monolithic, nearly impenetrable concrete core. Combined with steel reinforcements, an ICF wall is impact-resistant and can withstand winds up to 250 mph (402 kph).

This strength makes ICF buildings disaster-resilient and proven to endure hazardous weather, including natural disasters like earthquakes, tornadoes or hurricanes. In fact, the United States military builds its structures with ICFs to protect against potential bullets and explosions.

Conversely, the seams along a CMU block wall leave it vulnerable to extreme movement, flying debris and high winds. To achieve equivalent structural integrity of an ICF assembly, perimeter steel columns would need to be added to the CMU walls.

For construction of the Florida Armed Forces Reserve Center in St. Petersburg, Florida, designer William Murray opted for Insulated Concrete Forms due to their high level of protection, stating that “masonry construction would require reinforcement in every block at a cost 25% greater than the cost for ICF construction.”

Are ICFs easier to install than CMUs?

Yes. Building with Insulated Concrete Forms streamlines wall construction, reducing time and labor compared to CMUs. Even in 8-foot-lengths, lightweight ICFs are less strenuous for installers to move around the jobsite than heavy cinder blocks. ICF blocks snap together when stacking and can cover more ground faster than the standard cinder block sizes. The EPS foam of Insulated Concrete Forms can also be trimmed on-site, making them more adaptable than cinder blocks.

Cinder blocks are more cumbersome to transport and cut on the construction site. And after installation, CMU walls still require projects to hire trades for proper insulation and waterproofing, prolonging the duration and increasing the cost of construction.

How are ICFs beneficial for trade workers?

Electricians, plumbers and HVAC technicians may be more familiar with conventional wood-frame, steel-frame, or CMU construction, but once they understand ICF technology, they’ll see how simple it is to work with. Even the newest workers can quickly learn the process to dispel any misconceptions of this seemingly new technology. After their first ICF job, the trades will see that they can install plumbing, electrical lines, and heating and cooling systems in ICF buildings with ease. As more and more structures are being built with Insulated Concrete Forms, companies with ICF experience in their scope of work will set themselves apart from their competitors.

Do ICFs offer increased energy efficiency over CMUs?

Yes, ICFs are more energy efficient than CMUs, because of their two sides of continuous insulation and thermal mass that create an airtight building envelope. The R-values of ICF walls vary depending on the size of the concrete core and the foam thickness, but the majority are rated at R-23 or higher. Nudura offers even higher-performing ICF options that achieve up to R-48.

CMUs have innate R-values ranging from R-4 to R-14, which need significant additional insulation after stacking the cinder blocks to attain comparable energy performance. This extra step is already built into the Insulated Concrete Form assembly, but adds substantial cost, time and labor to a CMU project.

Are ICFS more cost-effective than CMUs?

When you factor in all the components of an exterior wall assembly, yes, ICFs are more cost-effective than CMU. By combining multiple building steps into one, Insulated Concrete Forms reduce time and expenses during the construction process, with the financial savings extending long after the building is occupied.

When you factor in all the components of an exterior wall assembly, yes, ICFs are more cost-effective than CMU. By combining multiple building steps into one, Insulated Concrete Forms reduce time and expenses during the construction process, with the financial savings extending long after the building is occupied.

ICFs are light-weight and stackable, which maximize freight loads for lower transportation costs compared to cinder blocks. In addition, with ICF construction, the structural walls and insulation are completed by one sub-contractor so there is less time and money spent on the coordination of trades. The energy efficiency and durability of ICF buildings also minimizes operational costs for the owner by cutting their ongoing utility bills and maintenance needs.

In comparison, CMUs increase labor, time and material expenses of the wall construction. The initial bid of concrete masonry can seem more economical, but once the price of the necessary rebar, embeds, lintel steel and insulation are included, the actual whole-wall cost is much more expensive. Cinder block installation is more labor-intensive than ICFs and may require more repairs over the life of the structure, which adds to its price tag.

Do ICFs or CMUs offer more design flexibility?

ICFs are better than CMUs when it comes to design versatility. Insulated Concrete Forms are available in different shapes, sizes, curves and corner configurations, so they can be easily integrated into more complex layouts and to reach higher performance standards. Some manufacturers will even customize ICFs for job-specific applications.

Because ICF walls are seamless through the entire height of the building, they are more effective at transitioning between below-grade and above-grade conditions. See how to connect ICFs to the roof here. This continuity limits the connection points of dissimilar materials that are prone to air and water leakage, easing the architectural process for designers and the installation procedures for contractors.

CMUs are typically only used for foundations and basements, and therefore require careful detailing between the concrete masonry walls and the framing above-ground. Cinder blocks are also only manufactured in straight lines, making it difficult to accommodate any complicated building geometries like radius walls.

CONTACT US

We’re committed to supporting homeowners and design professionals who are interested in or use our products. We’re always happy to help and provide more information.